[ad_1]

Defining low-carbon hydrogen

The different colors of hydrogen are linked to specific manufacturing processes, each associated with a distinct environmental footprint indicated by its respective colors. Despite this, these colors suffer from a lack of clear definition. To address this ambiguity, we therefore recommend the use of “low-carbon hydrogen”.

According to the latest EU delegated acts, the condition for hydrogen to be considered low-carbon is when the emissions of the production life-cycle are less than 3.38 kg CO₂ e/kg H₂. This provides a standardized measure, offering clarity in categorizing hydrogen based on its environmental impact. It makes no doubt that low-carbon hydrogen will play a major role in the industry’s energy transition and the future of transportation. All of those promising applications require pure hydrogen and impurities removal is often seen as a black box when in reality there are a lot of technologies (and chemistry) behind.

What hydrogen for what purity?

Hydrogen can be produced by several manufacturing processes (steam methane reforming, gasification, water electrolysis) or can even be found underground. Naturally, depending on the manufacturing process, hydrogen will come together with an array of impurities: oxygen, water, carbon oxides and sulfur, just to name the major components.

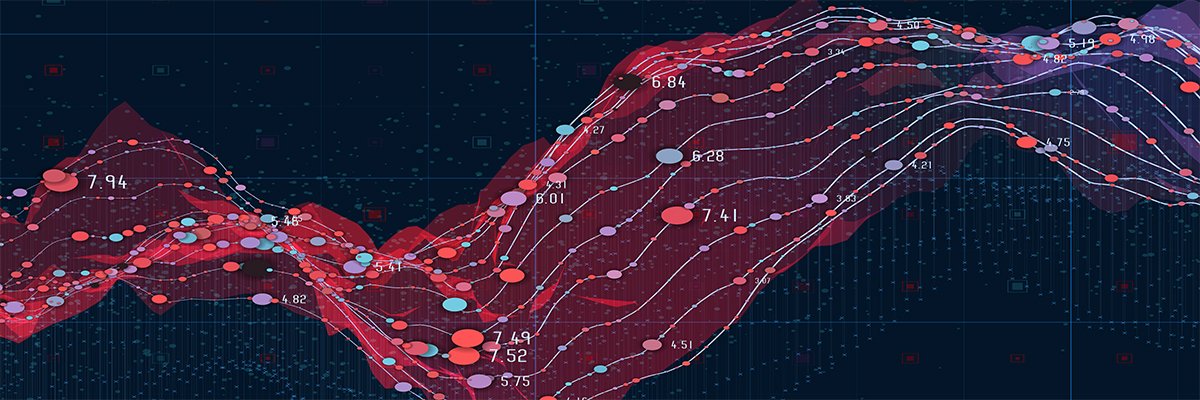

Table 1 summarizes the different impurities observed depending on its manufacturing process.

Maqvi News #Maqvi #Maqvinews #Maqvi_news #Maqvi#News #info@maqvi.com

[ad_2]

Source link